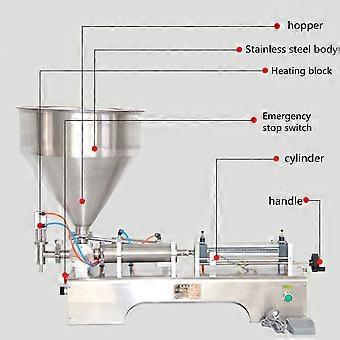

50500ml Double Nozzle Pneumatic Paste Filling Machine for Cream Shampoo with Precise Control

Livrare GRATUITĂ

50500ml Double Nozzle Pneumatic Paste Filling Machine for Cream Shampoo with Precise Control

- Marcă: Unbranded

50500ml Double Nozzle Pneumatic Paste Filling Machine for Cream Shampoo with Precise Control

- Marcă: Unbranded

Economii 4.600,00 RON (33%)

Preț recomandat

Politica de retur pe 14 zile

Economii 4.600,00 RON (33%)

Preț recomandat

Politica de retur pe 14 zile

Metode de plată:

Descriere

50500ml Double Nozzle Pneumatic Paste Filling Machine for Cream Shampoo with Precise Control

- Marcă: Unbranded

- Categorie: Fabricație

- ID Fruugo: 459863406-968105377

- EAN: 6161583584746

Informații privind siguranța produsului

Vă rugăm să consultați informațiile despre siguranța produsului specifice acestui produs prezentate mai jos

Următoarele informații sunt furnizate de comerciantul independent terț care vinde acest produs.

Etichete de siguranță pentru produse

Livrări şi Returnări

Expediat în 24 de ore

-

STANDARD: GRATUIT - Livrare între vin. 30 ianuarie 2026–mar. 17 februarie 2026 - GRATUIT

Livrare de la China.

Facem tot ce ne stă în putinţă să ne asigurăm că produsele comandate de dumneavoastră vă sunt livrate în întregime şi conform specificaţiilor. Cu toate acestea, dacă primiţi o comandă incompletă sau articole diferite de cele comandate, sau aveţi alt motiv pentru care nu sunteţi mulţumit de comandă, puteţi returna comanda sau orice produse incluse în comandă şi primiţi o rambursare completă pentru articole. Vizualizaţi întreaga politică de returnare

Detalii de conformitate a produsului

Vă rugăm să consultați informațiile de conformitate specifice acestui produs prezentate mai jos.

Următoarele informații sunt furnizate de comerciantul independent terț care vinde acest produs.

Producător:

În continuare se prezintă informațiile de contact ale producătorului produsului relevant vândut pe Fruugo.

- Whosalem

- Shenzhen Tumi Technology Co., Ltd.

- 202-03, Jinhe Building, 8 Xinhe Street, Maan Tang, Bantian

- Longgang, Shenzhen, Guangdong

- China

- Shenzhen

- CN

- 518129

- pettynfnef@outlook.com

- 13332965772

Persoana responsabilă în UE:

În continuare se prezintă informațiile de contact ale persoanei responsabile din UE. Persoana responsabilă este operatorul economic desemnat, cu sediul în UE, care este responsabil pentru obligațiile de conformitate referitoare la produsul relevant vândut în Uniunea Europeană.

- Synertrade FR SAS

- Synertrade FR SAS

- 9 rue du Bat d'Argent

- Lyon

- France

- Lyon

- FR

- 69001

- info@syner-sarl.cn

- (+33)774555006

- https://seller.kuajingmaihuo.com/settle/qualification-service